Thermic Fluid Heaters

Solid Fuel Fired

Salient Features of This Model

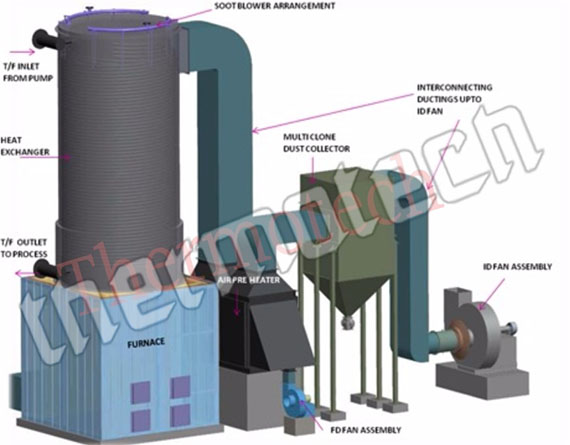

Our Solid Fuel Fired Thermic Fluid Heater is an advanced heating system that provides a reliable and efficient option for generating hot thermic Oil for a variety of applications.

The furnace of this model is customized to provide a variety of fuel options. We have carefully selected the right combustion grate, combustion volume, furnace height, and fuel feeding systems. These considerations allow our generator to achieve efficient combustion and minimize heat loss.

The coil design is made with optimal flow consideration which maximizes the heat transfer from flue gasses. Before being dispatched, our coils undergo rigorous 3-stage testing. This is a part of Thermotech’s strict quality measures to ensure our reliability and performance.

We also take specific measures when selecting booster fans, FD fans, and ID fans to match the perfect air-to-fuel ratio requirements of the fuel in use. This precision ensures the ideal quantity of air for combustion, resulting in energy savings and reduced power consumption.

Our approach to selecting the expansion tank capacity also follows a specific approach. We

consider the total holdup of the thermic oil and ensure that it meets the system’s unique

requirements. Similarly, the deaeration tank is designed after considering the flow and

temperature.

3 Pass Thermic Fluid Heater

Added Advantages

- Multiple Fuel Options

- Optimized Power Consumption

- Minimal Maintenance

- Energy Optimization

- New Modularized compact design

Safety Features and Controls

- Temperature Control for Thermic Fluid Our high-tech temperature control system comes with a digital temperature indicator and controller. It is programmed to automatically shut down the ID/FD fan when the temperature reaches a pre-set limit. The system restarts when the temperature falls within the desired range, in order to maintain system temperature at optimal levels.

- Stack Temperature Control To prevent excessive stack temperatures, we use a temperature controller that triggers an ID/FD shutdown and activates an audible alarm when the stack temperature goes beyond the preset temperature.

- Thermic Fluid Flow Monitoring Our system consists of a differential pressure switch placed across the inlet and outlet headers. This component works as a signalling device. It sends out a ‘Low or No Flow’ alarm when the thermic fluid pressure drops in the coils.

- Thermic Fluid Level Monitoring We have also integrated a visual level indicator and a float-actuated lever switch in the expansion tank. These components trigger an alarm when the thermic fluid level dips below the recommended limit.

- Thermic Fluid Pump Motor Failure Protection If the thermic fluid motor pump fails, our

electrical interlocks become functional and deactivate the ID/FD fan. This prevents any

adverse effects on the system. - Power Failure Protection Our system comes with a diesel engine drive that maintains thermic fluid circulation during power outages. This prevents fluid degradation and potential overflow.

- Furnace Bed Temperature Control (FBC Units)We have integrated a digital temperature

indicator and controller for FBC units. The system automatically cuts off the ID/FD fan if the

furnace bed temperature exceeds safe values.

4 Pass Thermic Fluid Heater

Applications

The Thermotech Thermic Fluid Heaters are meticulously designed to accommodate a wide range of commercial and special fuels available in the market. They find their utility across diverse industries.

- Industries We Serve – Chemical, Textile, Technical Textile, MDF and Particle Board, Plywood and Laminates, Oil and Gas, Packaging, Rubber, Latex, Automobile, Paint, Leather and Vinyl, Paper, Automobile Solar, Pharmaceuticals, Food Processing, Metal Industries, and more.

- Fuel Flexibility – Our thermic fluid heaters are designed to handle a range of fuels, offering remarkable adaptability. These include briquettes, sawdust, groundnut shells, bagasse, petroleum coke, rice husk, palm waste, lignite, coffee husk, coal, rice straw, coconut waste, mustard straw, cotton stalk, wood chips, and more.

- Unwavering Quality Assurance – We take pride in our commitment to quality, holding an ISO 9001, 14001 & 45001 certificate since decade. Through this commitment to quality, we provide top-notch heating solutions to our customers.

Oil/Gas Fuel Fired

Salient Features of This Model

At Thermotech, we offer a range of Thermic Fluid Heaters, available in both Horizontal and Vertical Models. These heaters are designed to efficiently heat thermic fluid up to a maximum temperature of 345° C, operating at near atmospheric pressure. The heaters come with an impressive efficiency of up to 94% based on the Nett Calorific Value (NCV) of Oil and Gas fuels and deliver exceptional performance.

- Advanced Heat Exchanger – The Main Heat Exchanger is designed with precise engineering and high-quality materials. It comes with an integrated combustion chamber crafted from robust materials such as High Heat Resistant Steel Tubes (BS 3059 P-1) or Seamless Pipes (SA106 Gr.B S40) or Alloy Steel of substantial size. The design comes with a twin concentric multi-start helical coil which is carefully inserted into M.S/C.S/S.S Shell with reinforced structural support for precise alignment.

- Three-pass Configuration – The heat exchange process follows a three-pass configuration on the flue gas side, optimizing heat transfer through a counter-current flow principle. The combustion chamber is carefully designed to maintain a safe distance between the coil tube surface and the burner flame. This meticulous design ensures not only efficient heat transfer but also extends the life of the thermic fluid by minimizing film temperatures. It also guarantees the safety of the helical coil tube, thereby safeguarding the

entire heat exchanger. - The Improved “TSH” Series – Horizontal Model – The heaters of this model represent an improved version, characterized by exceptional design and use of cutting-edge technologies and materials. These improvements have increased the unit’s efficiency to an impressive 93%, resulting in substantial energy savings and simplified maintenance. The emissions are also significantly reduced, and the heaters can be seamlessly integrated with PLC and SCADA systems.

- Environmentally Conscious Designs– Working towards our environmental responsibility and enhanced combustion efficiency, we have incorporated technological advancements. This allows for efficient recovery of stack heat from the exhaust flue gasses on the primary heat exchanger through a Combustion Air Pre Heater (CAPH). This ingenious system preheats fresh combustion air before it reaches the burner, contributing to improved combustion efficiency, reduced stack temperatures, lower fuel consumption, and ultimately, a more eco-friendly operation.

Capacity

Our Thermic Fluid heaters come in various capacities, ranging from 0.1 MM KCal/ hr to 15 MM Kcal/hr. This ensures that we can meet a wide range of heating requirements. The heaters are capable of reaching a maximum of 345° C, making them suitable for a diverse set of industrial applications.

Applications

The Thermotech Hot Oil Heaters are meticulously designed to accommodate a wide range of commercial and special fuels available in the market. They find their utility across specified industries.

- Industries We Serve – Specialty Chemical, Petrochemicals & Oil and Gas.

- Fuel Flexibility – Our hot oil heaters are designed to handle a range of fuels, offering remarkable adaptability and cost-effective fuel options. These include a variety of gasses including natural gas, refinery gas, off-gasses, stripper column off-gas, and hydrogen, and liquids like diesel, furnace oil, crude oil, and more.

- Unwavering Quality Assurance – We take pride in our commitment to quality, holding an ISO 9001, 14001 & 45001 certificate since decade. Through this commitment to quality, we provide top-notch heating solutions to our customers.