Hot Air Generator

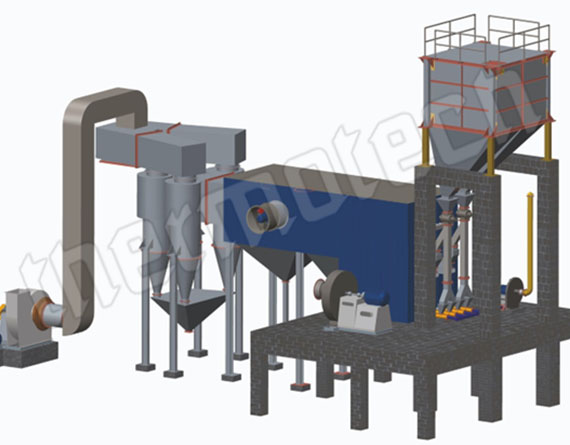

Direct Fired Hot Air Generator

Salient Features of This Model

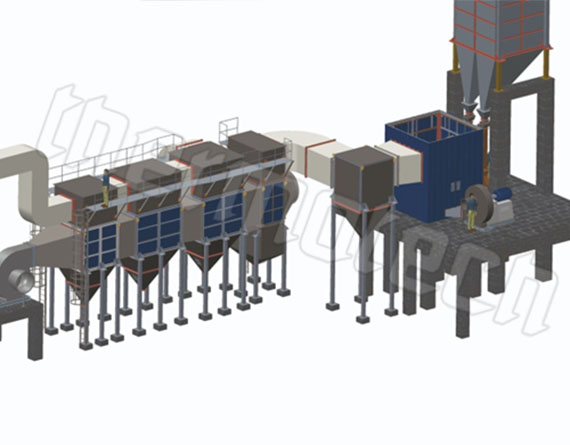

Our horizontal multi-pass direct-fired Static Grate / FBC (Fluidized Bed Combustion) hot air generator is designed with a strong emphasis on fuel flexibility, allowing it to efficiently burn a wide range of materials. This includes materials like sawdust, rice husk, pulverized coal, wood, biomass and various free-flowing fuels. This versatility enables the generator to achieve high and medium process temperatures without the need for operating pressures.

Some of the features of this model are:

- High-Capacity Heating System – This generator comes with a high-capacity heating system, ensuring that it can meet substantial heating requirements effectively.

- Optimized Combustion – The fluidized bed combustion (FBC) technology ensures efficient and thorough combustion of fuels, enhancing energy utilization and reducing waste.

- Temperature Range –It is capable of achieving high and medium process temperatures without the necessity of operating pressures, making it suitable for a wide range of industrial applications.

- Multi-Fuel Option– It offers the flexibility to utilize multiple fuel types, making it adaptable to varying fuel availability and cost considerations.

- High Durability-Designed for durability, this generator requires minimal maintenance, reducing downtime and operational disruptions.

- Multi-Pass Design – The multi-pass design of the system optimizes heat transfer and energy efficiency, ensuring maximum utilization of the generated heat.

- User-Friendly Systems – Its user-friendly design ensures ease of operations and maintenance, reducing the need for specialized manpower.

Benefits

- Fuel Cost Savings – Its fuel flexibility allows businesses to choose cost-effective and readily available fuel sources, reducing overall fuel expenditure.

- Process Versatility – This generator can cater to a wide range of industrial processes with varying temperature requirements, providing versatility for diverse applications.

- Low Maintenance – The rugged construction and efficient design minimize maintenance requirements, reducing downtime and associated costs.

- Environmental Friendliness – Efficient combustion and reduced emissions contribute to a more environmentally friendly operation, aligning with sustainability goals.

- Reliable Heat Source – With the ability to generate hot air at different temperatures, it serves as a dependable heat source for industrial processes.

Capacity

Thermotech offers a comprehensive selection of direct-fired hot air generator models designed to cater to diverse customer requirements. These models come in capacities spanning from 0.5 MM KCal/hr to 20 MM KCal/hr with standard outlet temperatures

reaching 420° C. With an overall efficiency rating of 90 % (+/-2%) on NCV (Net Calorific Value), this generator maximizes energy utilization, minimizing waste and operational costs.

Applications

The Thermotech Hot Air Generators are meticulously designed to accommodate a wide range of commercial and special fuels available in the market. They find their utility across diverse industries.

- Industries We Serve – Drying Processes, Paints Industry, Heat Treatment Plants, Pharma, Food & Beverages, Metalworking, Agriculture, Wood Processing, Paper and Pulp, Textiles, Chemicals, and more.

- Fuel Flexibility – Our Hot Air Generators are designed to handle a range of fuels, offering remarkable adaptability. These include sawdust, Biomass, rice husk, pulverized coal, and any type of free-flowing fuel.

- Unwavering Quality Assurance – We take pride in our commitment to quality, holding an ISO 9001, 14001 & 45001 certificate since decade. Through this commitment to quality, we provide top-notch heating solutions to our customers.

Indirect Fired Hot Air Generator

Salient Features of This Model

Our horizontal three-pass indirect-fired shell and tube-type hot air generator represents an innovative design, crafted for maximum efficiency. This versatile system can run using different fuels including heavy oils, light oils, and gasses. It is designed to provide low process temperatures without needing operating pressures.

- Multi-Pass Hot Air Generation – This generator employs a unique multi-pass system. It features a radiation chamber crafted from stainless steel plates of the appropriate volume as per capacity. This chamber is designed with two expansion joints below to withstand thermal shock from alternating hot and cold conditions. The remaining shell components are constructed from M.S. plates and sheets, forming multiple passes for the flue gas and hot air generation.

- Centrifugal Blower Fan – The system uses a centrifugal blower fan, coupled with a suitably powered motor, positioned at the inlet of the hot air generator. This fan efficiently delivers the required volume of fresh air for the process.

- Advanced Burner – An imported single or two-stage light oil monoblock / Dualblock burner, complete with a duplex filter, is skillfully mounted on the hot air generator. This ensures smooth and reliable operation.

- Low-Temperature Operation– It is designed to achieve low process temperatures without the requirement for operating pressures, making it suitable for processes with specific temperature constraints.

- Three-Pass Configuration-The three-pass design optimizes heat exchange, enhancing overall energy efficiency and minimizing heat loss. This feature also makes the generator a cost-effective and environmentally friendly solution.

Benefits

- Fuel Versatility – The system accommodates a wide range of fuels, including heavy oils, light oils, and gasses, enhancing flexibility in fuel selection.

- Low Maintenance – Its robust design requires minimal maintenance, reducing operational disruptions and costs.

- High Heating Capacity – This generator offers a high-capacity heating system, meeting substantial heating requirements efficiently.

- Independent Operations – This type of hot air generator can be utilized independently, eliminating the need for steam boilers or thermal fluid heaters.

- Ease of Installation – This entire unit is securely placed on a common base frame for stability and ease of installation.

- User-Friendly – Designed for ease of use, this system is operator-friendly, ensuring hassle- free operation and maintenance.

Capacity

Thermotech offers a comprehensive selection of indirect-fired hot air generator models designed to cater to diverse customer requirements. These models come in capacities spanning from 0.5 MM KCal/hr to 8 MM KCal/hr with standard outlet temperatures reaching 280° C. Upon request, we also offer customized systems with higher outlet temperatures. With an overall efficiency rating of 85 % (+/-2%) on NCV (Net Calorific Value), this generator maximizes energy utilization, minimizing waste and operational costs.

Applications

The Thermotech Hot Air Generators are meticulously designed to accommodate a wide range of commercial and special fuels available in the market. They find their utility across diverse industries.

- Industries We Serve – Chemical or Dyestuff industries, Food and Beverages, Salt Drying industries, Laundry, Paints, Oven heating, Textile, Spray Dryer, Spin Flash Dryer, and more.

- Fuel Flexibility – Our hot air generators are designed to handle a range of fuels, offering remarkable adaptability. These include heavy oils, light oils, and gasses.

- Unwavering Quality Assurance – We take pride in our commitment to quality, holding an ISO 9001, 14001 & 45001 certificate since decade. Through this commitment to quality, we provide top-notch heating solutions to our customers.